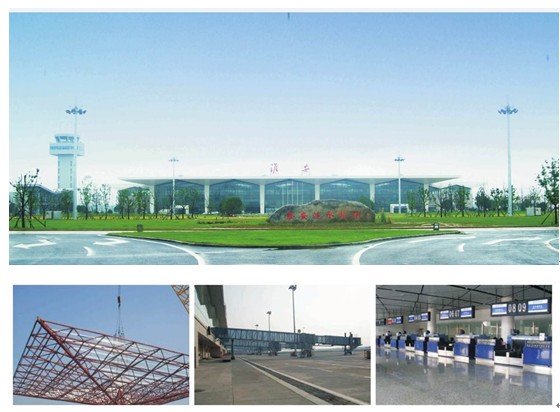

Muyang Steel Silo Engineering

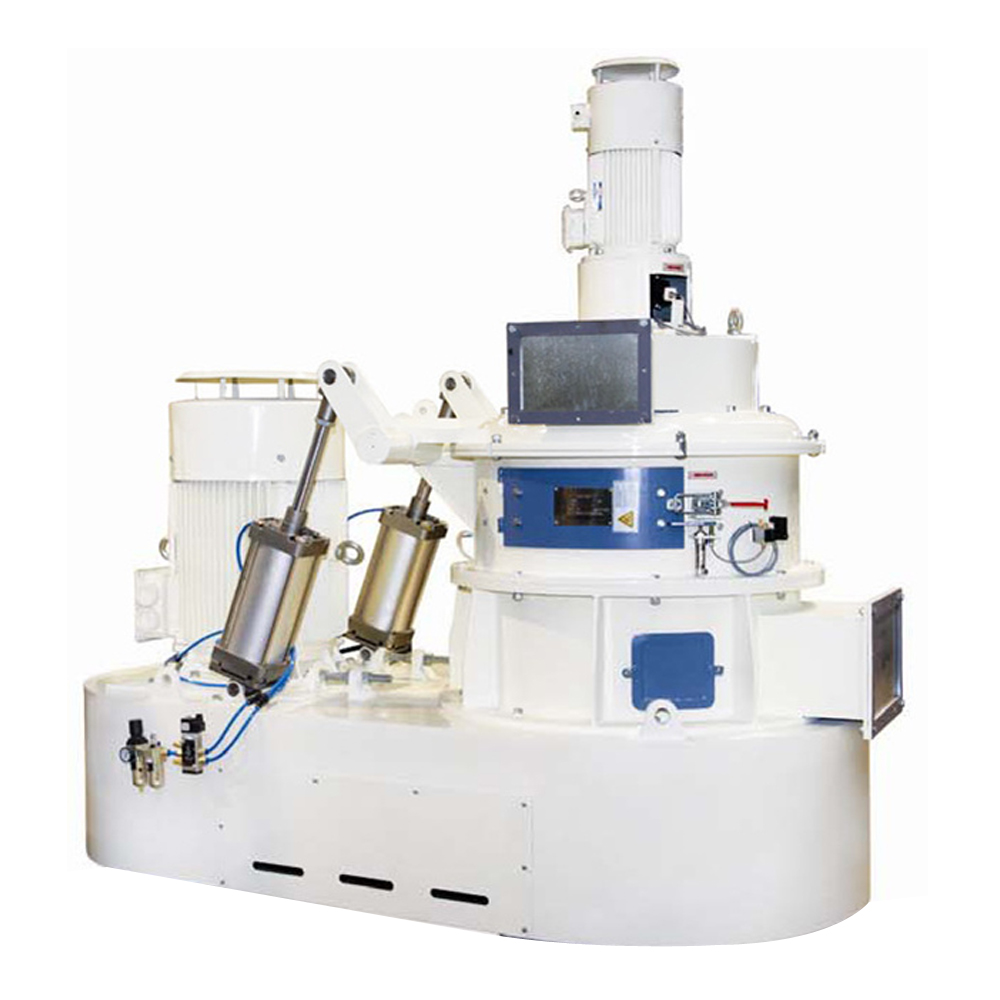

Muyang is a nationally recognized leader in the design and construction of reinforced steel silos. Muyang prefabricated corrugated steel silo using a full U.S. latest manufacturing technology and equipment, equipped with the most advanced computer system that provides users with 10 to 16,800 tons of different models of flat, conical bottom, fluidizing material and porous material discharging, its unique in China.

The steel silo is for anchoring on a concrete foundation or steel structure with an extensive range of accessories. And one single-silo capacity is up to 18,000 tons with comprehensive configurations to meet customers' different requirements. We are able to examinate any bulk material in our laboratories and Technology Center with standardized range of accessories.

Optimum workmanship - no corners and edges on grain storage silo inside, high-quality surfaces, low-scratch method used for shaping and certified welding quality. We design our silos as per your individual requirements. It is suitable for bulk solid materials with good and poor flowability (plastic powders, recycled material, pellets, and flowable elastomers).

Muyang is the world's leading overall storage facilities and engineering solutions provider, in addition to providing storage silo, spiral silo and insulation silo, but also providing a comprehensive package of equipment and systems, including transportation equipment, drying equipment, as well as providing the overall design, construction , integration services.

The article is from : http://muyangsales.edublogs.org/2014/01/03/muyang-steel-silo-engineering-2/

The steel silo is for anchoring on a concrete foundation or steel structure with an extensive range of accessories. And one single-silo capacity is up to 18,000 tons with comprehensive configurations to meet customers' different requirements. We are able to examinate any bulk material in our laboratories and Technology Center with standardized range of accessories.

Optimum workmanship - no corners and edges on grain storage silo inside, high-quality surfaces, low-scratch method used for shaping and certified welding quality. We design our silos as per your individual requirements. It is suitable for bulk solid materials with good and poor flowability (plastic powders, recycled material, pellets, and flowable elastomers).

Muyang is the world's leading overall storage facilities and engineering solutions provider, in addition to providing storage silo, spiral silo and insulation silo, but also providing a comprehensive package of equipment and systems, including transportation equipment, drying equipment, as well as providing the overall design, construction , integration services.

The article is from : http://muyangsales.edublogs.org/2014/01/03/muyang-steel-silo-engineering-2/

muyangsales - 3. Jan, 09:33