Twin-Screw Cooking Extruder

I believe there are too many people eating puffed food, you know a lot of puffed food is made by extruder machine which belongs to a food processing equipment, many puffed food in the market, such as soy, rice, corn and wheat, is mainly produced by the machine from mechanical energy into heat, with the heat by machine moving to cook the grains, after the process, the food's volume greatly becomes larger.

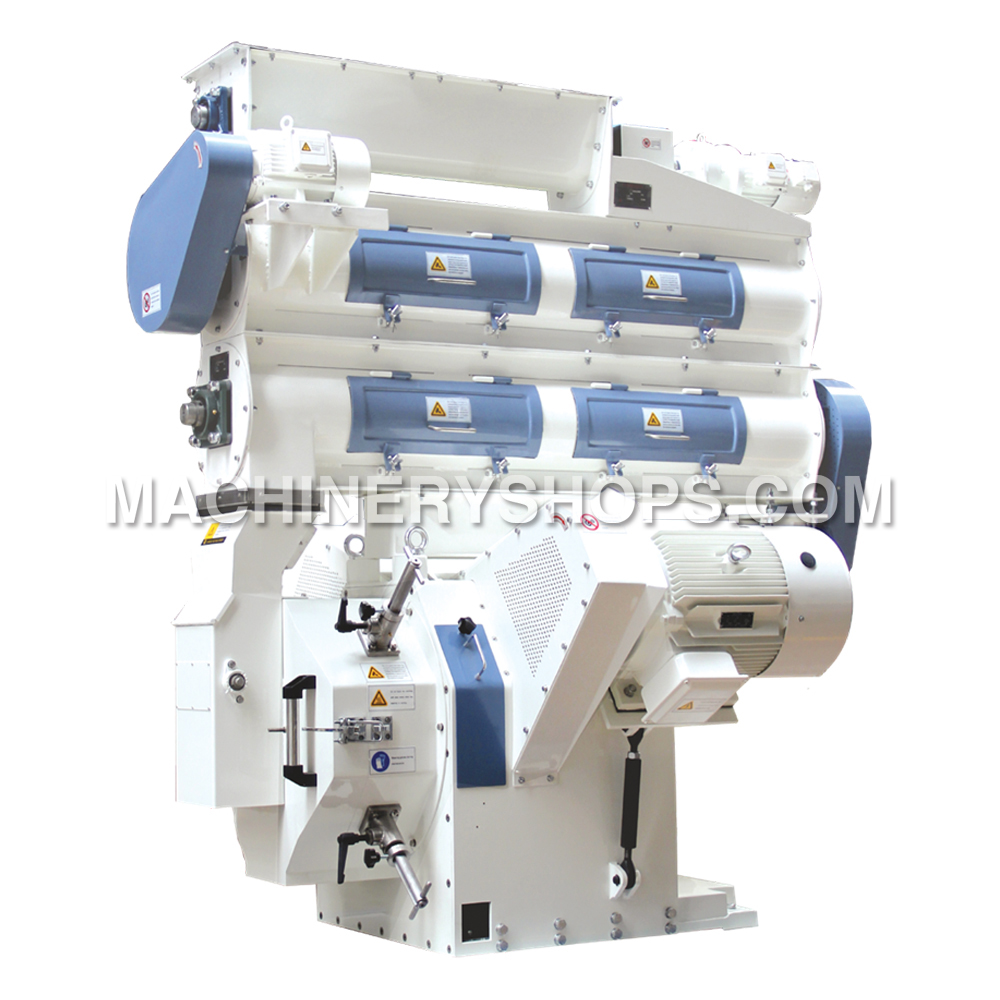

Muyang can provide you with all types of extruders with high quality and performance which can be used flour puffing, cereal puffing, and soybean puffing. Muyang MY Twin-screw Extruder has two screws, the upper single barrel conditioner ensures rational rotating speed and full mixing of water steam and raw materials and the lower layer different diameter cylinder conditioner, through adjusting paddles, raw materials fullness can be increased.

Now the Twin-screw Extruder presents you its brilliant factor, it is easy to operate, as its PLC and touch screen for convenient control, and the by-pass provides for avoiding blockage. While, this machine is getting high efficiency with the optimal chamber groove and screw flight profiles, minimum SME input, efficient DDC conditioner and jacketed barrel with stabilized and faciliated extrusion, maximum energy utilization, and unique suspending cutter. It also has more flexibilities with modularized barrel and screw strucutre with many add-ones, adaptable to varied high-fat or moisture.

Also, Muyang can provide you with all necessary kinds of feeding machines, and you have any questions here, you can leave your comments here.

Muyang can provide you with all types of extruders with high quality and performance which can be used flour puffing, cereal puffing, and soybean puffing. Muyang MY Twin-screw Extruder has two screws, the upper single barrel conditioner ensures rational rotating speed and full mixing of water steam and raw materials and the lower layer different diameter cylinder conditioner, through adjusting paddles, raw materials fullness can be increased.

Now the Twin-screw Extruder presents you its brilliant factor, it is easy to operate, as its PLC and touch screen for convenient control, and the by-pass provides for avoiding blockage. While, this machine is getting high efficiency with the optimal chamber groove and screw flight profiles, minimum SME input, efficient DDC conditioner and jacketed barrel with stabilized and faciliated extrusion, maximum energy utilization, and unique suspending cutter. It also has more flexibilities with modularized barrel and screw strucutre with many add-ones, adaptable to varied high-fat or moisture.

Also, Muyang can provide you with all necessary kinds of feeding machines, and you have any questions here, you can leave your comments here.

muyangsales - 10. Jul, 11:07