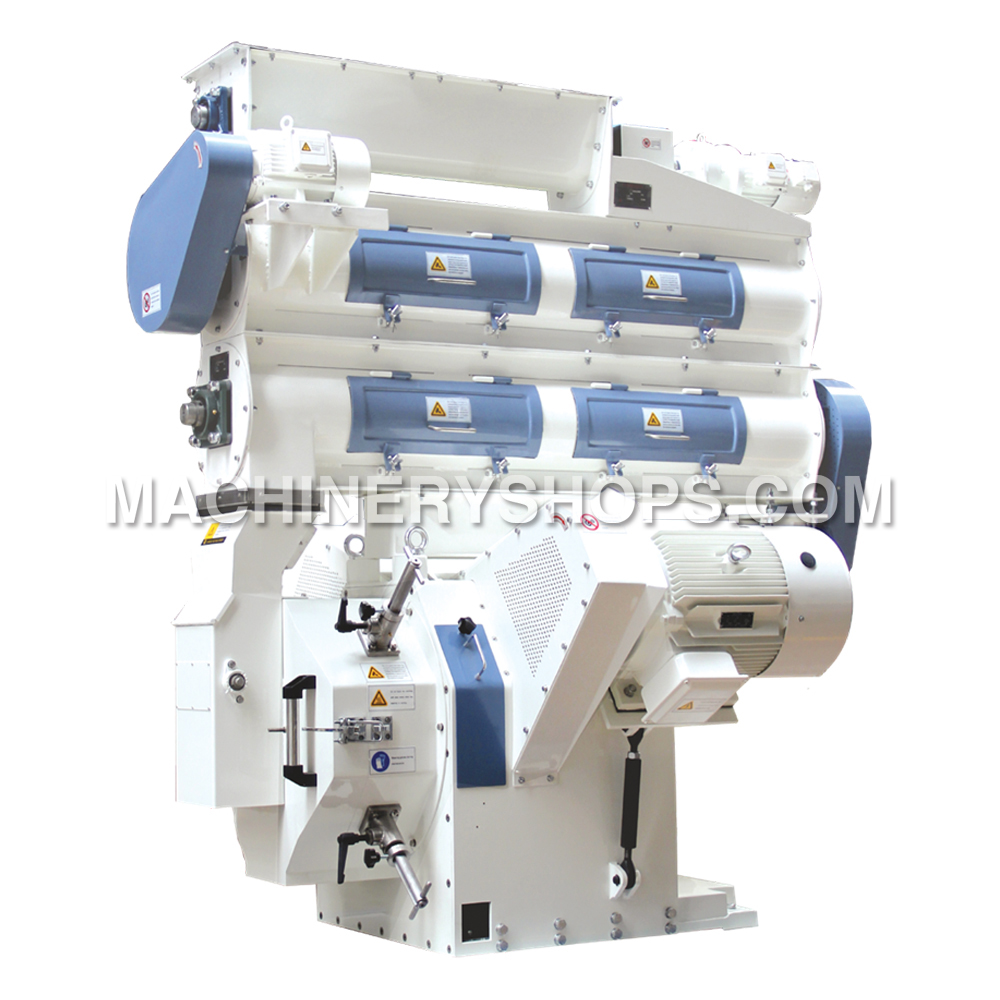

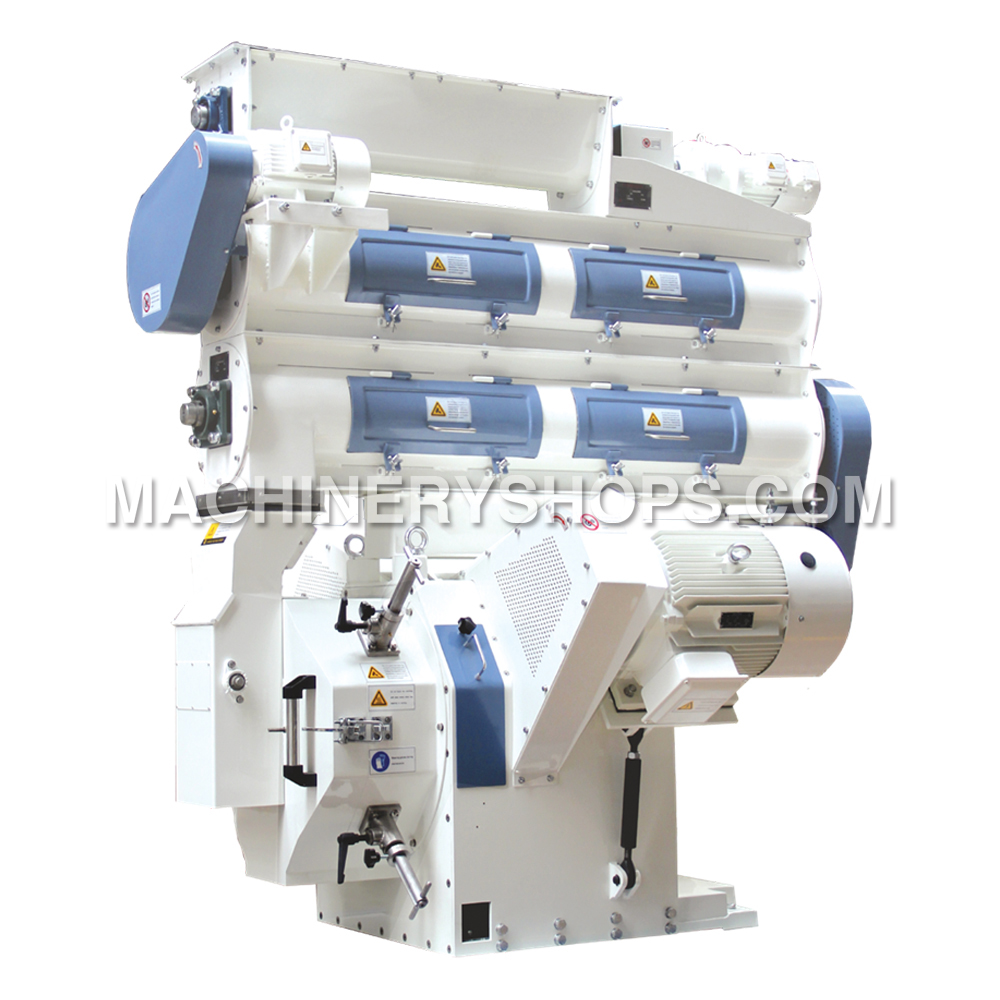

Pelleting Machine MUZL350/420

Why Choose Muyang Pellet Machine

Pellet machine is used for the development of the desired particle powder. Its main feature is the screen stencil is easily installed and removed, and the tension can be also adjustable. Seven corner roller is easy to clean and remove. Mechanical drive system totally enclosed in the body, together with the lubrication system. Pelleting Machine MUZL350/420 is based on the requirements of GMP design and manufacture of new models, all with the whole appearance quality stainless steel closed. So that the whole looks clean and beautiful, especially the use of metal wire mesh or stainless steel mesh. The quality and the particles have a greater increase of economic efficiency.

Advantages: Smooth and steady, Transfer surging power

1. Manufacturing according to the international advanced technology standard;

2. Advanced two-stage drive system, with stable and reliable performance and low noise;

3. Imported key components ensuring the long service life and low cost for maintenance;

4. The principal axis forged by alloy steel, with high durability and good tenacity;

5. With semi-automatic oil adding device, easy to lubricate;

6. Widely used for pelleting the high-quality livestock and poultry feed, aquatic feed, compound fertilizer and other materials.

How to use the pellet machine rightly

1. Use method: start the machine, pour the mixed materials into the bucket, swing by the rotating drum role, through the wire mesh to form particles fall into containers, if you use crushed pieces, you should gradually added, not to fill so fast, in ordre to protect against pressure, making the screen wearing.

2. Notes: You should not shovel when the powder stays there avoiding hurt your hands or stop working.

3. Speed options: You should make the right choice according to different speeds. Generally, you can choose the suitable one as it is wet or dry. Dry goods faster, wet product should be slow, but its scope can not be unified regulations, according to the actual operating conditions.

Pellet machine is used for the development of the desired particle powder. Its main feature is the screen stencil is easily installed and removed, and the tension can be also adjustable. Seven corner roller is easy to clean and remove. Mechanical drive system totally enclosed in the body, together with the lubrication system. Pelleting Machine MUZL350/420 is based on the requirements of GMP design and manufacture of new models, all with the whole appearance quality stainless steel closed. So that the whole looks clean and beautiful, especially the use of metal wire mesh or stainless steel mesh. The quality and the particles have a greater increase of economic efficiency.

Advantages: Smooth and steady, Transfer surging power

1. Manufacturing according to the international advanced technology standard;

2. Advanced two-stage drive system, with stable and reliable performance and low noise;

3. Imported key components ensuring the long service life and low cost for maintenance;

4. The principal axis forged by alloy steel, with high durability and good tenacity;

5. With semi-automatic oil adding device, easy to lubricate;

6. Widely used for pelleting the high-quality livestock and poultry feed, aquatic feed, compound fertilizer and other materials.

How to use the pellet machine rightly

1. Use method: start the machine, pour the mixed materials into the bucket, swing by the rotating drum role, through the wire mesh to form particles fall into containers, if you use crushed pieces, you should gradually added, not to fill so fast, in ordre to protect against pressure, making the screen wearing.

2. Notes: You should not shovel when the powder stays there avoiding hurt your hands or stop working.

3. Speed options: You should make the right choice according to different speeds. Generally, you can choose the suitable one as it is wet or dry. Dry goods faster, wet product should be slow, but its scope can not be unified regulations, according to the actual operating conditions.

muyangsales - 17. Jun, 10:35